PANTONE spot color printing and CMYK four-color knowledge

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2023-01-04 11:01:37

- Views:687

PANTONE spot color printing and CMYK four-color knowledge

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2018-06-08 15:40

- Views:

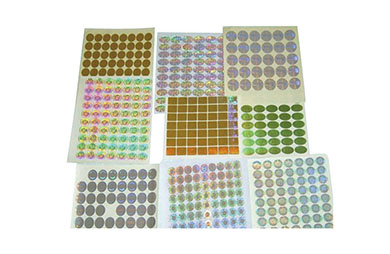

People in the industry don't know what the color card is, so it sometimes brings inconvenience to printing. The color card is a kind of reference used to convey color information. It is to compile PANTONE color numbers for various colors. You only need to tell the other party the color number, and the guests can find out what color it is. There are many types of color cards, and now the color cards produced by the American PANTONE company are the most widely used.

1. What is the difference and connection between PANTONE256C and PANTONE256U, PANTONE256M or PANTONE256matte?

They all said that the same spot color ink, PANTONE256, is the only one, which is PANTONE256. Difference: the tail number is "C": PANTONE256C means the effect of printing PANTONE256 on glossy coated paper, and its corresponding standard should be the spot color guide color card of coated paper; and so on, PANTONE256U means the For the effect of PANTONE256 printed on offset paper or special paper, its corresponding standard should be the spot color guide color card of uncoated paper; PANTONE256M or PANTONE256matte are the same, which means the effect of printing PANTONE256 on matte coated paper. The corresponding standard should be the spot color guide color card of matte paper (matte).

2. What is the difference between printing PANTONE spot color with four-color ink, namely CMYK, and directly using PANTONE standard spot color ink?

CMYK is made by superimposing up to four inks in the form of dots; using spot color ink is printing in the form of flat coating (solid color printing, dots is 100%) with one ink. Due to the above reasons, the former is obviously gray and not bright; the latter is bright and bright. Because spot color printing is a real color printing and is specified as a real spot color, CMYK printing spot color can only be called: analog spot color, showing the same spot color: such as PANTONE256C, there must be a certain difference in hue. Therefore, their standards are two standards. Please refer to "PantoneSolidToProcessGuide-Coated". If you print spot colors through CMYK, please refer to the analog version as the standard.

3. What is the coordination relationship of "spot color ink" in the whole process of design and printing?

This question is mainly for print designers. Usually designers only consider whether the design itself is perfect, and ignore whether the printing process can achieve the perfection of your work. There is little or no communication between the design process and the printing house, which will reduce the color of your work. Similarly, there may be less or no consideration for spot-color inks. Give an example to illustrate this type of problem, and you can understand its intentions by inferences.

For example: Designer A designed a poster poster, using PANTONE spot color: PANTONE356, one part of which is standard spot color printing, that is, on-the-spot (100% dot) printing, and the other part needs to be printed on the screen, which is 90% of the dots. They are all printed with PANTONE356. During the printing process, if the solid spot color part meets the standards required by the PANTONE spot color guide, the screened part will be "smeared". On the contrary, it is appropriate to reduce the amount of ink and the solid spot color part will be lighter. To PANTONE356's spot color guide standard.

Therefore, designers must consider or be aware of the blind spots of spot color ink on-the-spot printing and screen printing during the design process, and avoid blind spots to design the value of the screen. Refer to: Pantone Tims-Coated/Uncoated (PantoneTims-Coated/Uncoated) guide, the value of the screen should be in accordance with the value standard of PANTONE screen (.pdf). Or based on your experience, those values can be linked to those that cannot. You may ask whether this kind of contradiction is due to the poor performance of the printing press, or the operator’s technology, or the wrong operation method. This requires prior communication with the printing plant to understand the maximum performance of the printing press, the level of the operator, etc. Wait.

One principle: to make your work perfectly realized through printing, try to avoid the craftsmanship that cannot be realized by printing, so as to perfectly realize your creativity. The above example may not be particularly appropriate. It just wants to show that designers should consider the use of spot color inks and the communication issues with printers when designing.

4. The difference and connection between modern ink color matching technology and the international standard-PANTONE standard

The same point: the two are the same computer color matching; difference: modern ink color matching technology is the ink formula of the known color sample; the PANTONE standard color matching is the known ink formula for the color sample. Question: If you use modern ink color matching technology to find that the PANTONE standard formula is more accurate than the PANTONE standard color matching method, the answer is: there is already a PANTONE standard formula, why bother to ask for a formula, it is definitely not as accurate as the original formula. Another difference: modern ink color matching technology can be matched with any spot color, and the PANTONE standard color matching is limited to the PANTONE standard spot color. It is not recommended to use modern color matching technology to match PANTONE spot colors.

More news

CopyRight © 2022 Dongguan Wintop packaging Co., Ltd. All Rights Reserved.